Trailer Mouted Mud Tank /Mud Circulating System

Mud tank is the necessary equipment and slurry processing equipment supporting the mud circulation system for storing the drilling mud.

The mud tank is used to carry the mud from the wellhead to the Mud Pump. The mud tank is used together with the mud treatment equipment and serves as the treatment tank (also known as transition tank or grit chamber, etc.), slurry mixing tank, slurry storage tank and make-up tank in the solid control system.

Mud tanks are often used for Solid Control Equipment, mud storage, mud configuration etc., to meet the requirements of drilling solid control system,mud station and solid-liquid separation system. Mud tanks can be divided into metering tank, makeup tank, cooling tank, low-temperature drilling mud tank, trailer mounted mud tank, etc.

Mud tank is also called drilling mud tank, slurry mixing tank and slurry storage tank. It is an indispensable part of the mud circulation system and can be divided into vertical mud tank and horizontal mud tank. We can supply Mobile Frac Tank Mud Tank-500bbl、250bbl、220bbl etc..

Typically used for fracing wells in the oil and gas industry, a frac tank may also be used to store any liquids like run-off water, diesel fuel, glycol, oils, waste products, or for use when mining mud or drilling mud.

We has obtained the special quolifications of design and manufacturing of high and low pressure Pressure Vessels(A1,A2,D) and European and American manufacturing(ASME-U), relying on the technical advantages and market advantages of serving for petrochemical production for 30 years, the company has increased its business scope: the production project of "Design and manufacturing of mobile pressure vessels/production and modification of road special vehicles". (C2 tank truck, long tube trailer; C3 tube bundle container, tank container). To serve the special needs of the transportation of hazardous chemicals.

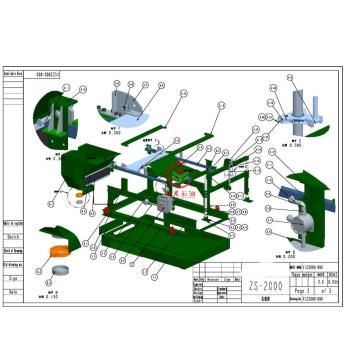

Specifications and parameters

500bbl Mobile Frac Tank Mud Tank

A:Tank

1,Capacity and compartments:500bbl in total,1 compartment

2,Tank shape:bottom is V-style ,side plate is wavy,roof is flat

3,Material of barrel : Q235Bcarbon steel,thickness is 5mm.

4,Shell cover: the two end is wavy,thickness is 6mm

5,Baffle: wave style,thicknes is 4mm,500mm man hole in every peice,4 piece in total

B:Pipe and Component

1,Manhole: open style manhole in the middle of roof

2,Pipe:one inlet on the rear,8''outlet on the front with 4 unit of 4'' fig quick coupling

3,Liquidometer: assemble on the front

C:Tank Accessories

1,Top walkway: galvanised steel net overspead on the middle roof of tank

2,Side bumper:

3,Rear bumper:made of U-steel

4,Ladder: assemble on the right side of middle of tank,made of steel tube

D:Chassis

1,Pin: 50# brand: JOST

2,Girder: 16Mn

3,Axle: one axle,spring suspention,brand :FUWA 13T

4,Rim and tire: 4 sets of 12R22.5 (FENGSHEN BRAND)with for sets of ZHENGXING steel rims

5,Electric wire: 24V electric system,seven pinhole socket assemble on the front

6,ELectric landing gear:2 sets on the both side of the tankers.electric power from bttery on the tractor.

E:Surface and inside coating

1,Kind of coating: Two primer,two finish paint

2,Color of tanker: depend on customer's requirement

3,The anti-rust inside paint: inside epoxy painting

220 bbl frac tank

1,Floor: 1/4 PL, 4" V-bottom with integral formed side channels

2,Floor Support: 10" channel longitudinal runners with formed 1/4 PL crossmembers

3,Walls: 1/4 PL solid welded, corrugated steel, corrugations 15" on center

4,Roof: Flat top, 1/4 PL solid welded with channel supports outside

5,Front/Rear: 1/4 PL solid welded, corrugated steel, 10" radius at vertical outside corners for the frac tank

6,Drain/Fill: 4" floor drain at rear end, 3" fill pipe to roof at rear, 4" suction line connection at front to sump, 8" flanged front manifold connection with turn down to floor. 8" exterior manifold with 4 - 4" couplings and plugs, Hammer Union sub, nut, and cap on ends

7,Gel Line: 4" mid high connection on curb side, 4" internal pipe with 3/4" holes located on 12" centers towards floor center, capped on rear end (ends near side manway)

8,Manway: 21" manway on front and side, 3 - non-sealed hatches on roof of the 220 bbl frac tank

9,Pick up: Standard 5th wheel king pin

10,Welds: All welds continuous except substructure crossmembers

Characteristics and features

▲Skid mounted with bumpers for easy movement on site.

▲Corner castings at the ISO position for easy handling.

▲Intermodal format allows cost effective mobilisation to any remote site.

▲V bottom internal format for easy drainage.

▲Manway access side access for easy access and cleaning.

▲Hatches in the roof.

▲Full blanked manifold on the rear to allow multiple units to be connected for larger projects.

▲Central Valve on from and rear to allow operation from either end.

▲Unit designed for the static storage of liquids on site.

▲Optional Ground operated air relief valve.

▲Supplied with removable robust frame bolted on the rear end to protect manifolds and to minimise damage any transport damage.

The ladder is made of the channel steel to take responsibility for the body, the footboard is made of the linearity netted steel plate.

The two-sided guard rail is installed the safe suspension hook.

We are major at Cementing and Fracturing Equipment, Gate Valve and wellhead Christmas Tree,Plunger Pumps and Mud Pumps, Flow line Products, Solid Control Equipment,Drilling Rigs and Work over Rigs Matching Equipment etc.

High quality & Steady quantity & Most competitive price will be sent for you.